SASS® 3100

Dry Air Sampler Operational Details

Performance Overview

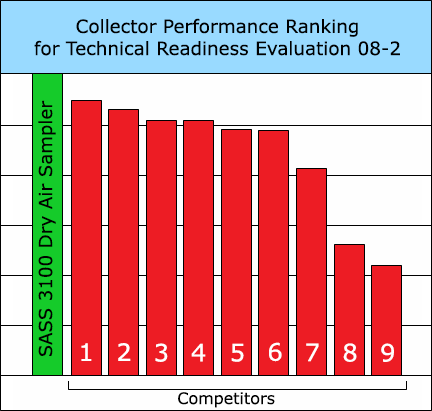

In a test that compared the performance of ten different wet and dry portable sampling systems from different manufacturers at the U.S. Army’s Edgewood CB Center, the SASS 3100 was the top performer, as shown in Figure 1.

The capture element is a 44mm diameter felt-like polymer disc. Each fiber in the disc has an electric field frozen into it. These fields induce a charge in aerosols passing through the filter and provide a capture mechanism much more effective than impaction; up to 50X more efficient than conventional glass or cellulosic filters. This “electret” media is stable to 70°C, is virtually inert, has a shelf life of 10 years, and has high holding capacity due to a large internal surface-to-volume ratio.

A microprocessor controls blower speed and provides diagnostics through fully dimmable LED indicators that warn when battery power is low and when the fan is not rotating. The unit may be controlled remotely via an RS-232 communications link, or with an optional RF link.

Ref.1: Test Report, Technology Evaluation Readiness Evaluation 08-2, CBR Technology Evaluation Branch, Edgewood CB Center, U.S. Army RDECOM, December, 2008.

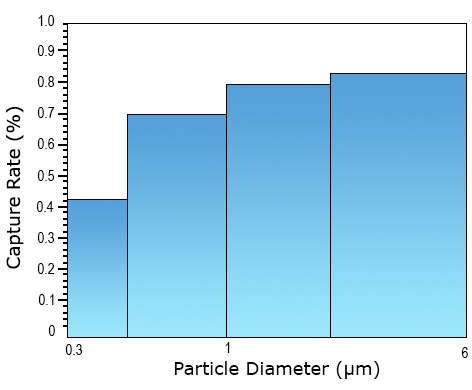

Disposable Filter Element

A key component is the disposable snap-on filter element (Figure 2). At the center of the element’s 60 mm diameter injection-molded frame is an acoustically-welded 44 mm diameter micro-fibrous capture disc. Figure 3 shows collection efficiency as a function of particle diameter for polystyrene test beads. Particles with diameters in the range of 0.3 to 0.5 µm are captured with almost 50% efficiency by the disc, while particles of 1.0 µm diameter or larger are captured at 80% or better efficiency.

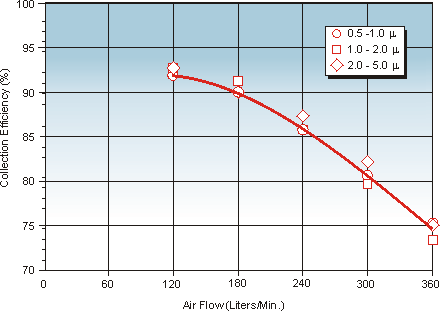

Collection efficiency changes by a relatively small amount over a suggested 50 to 300 liters/min. sampling range (See Figure 4). At an airflow of 120 LPM, the collection efficiency is about 92% for particles in the 0.5 to 5.0 micron size range. At the maximum airflow of 310 LPM, the collection efficiency falls to about 78-79% for similar-size particles, but the overall capture rate is nonetheless much greater at the higher flow rate.

Aerosol particle velocities are relatively low at the filter face as compared to particle velocities in sieve impactor collectors. At the maximum airflow of 320 liters/min., the effective air flow velocity at the filter face is about 3.5 m/sec. Impaction velocities on the order of 20 m/sec are common in sieve collectors used for biocontamination measurements under international standard ISO 14698-1. The relatively open structure of the filter (it has a void volume in excess of 96%) and the low face velocities offer relatively benign capture conditions for delicate microorganisms. As compared to conventional dry media such as glass filter papers and Nuclepore-style membrane filters, CBRN International’s electret media is much less harsh on captured organisms.

The surface-to-volume ratio of a microorganism is very large and surface mass transfer processes will rapidly equilibrate a microorganisms water content with the surrounding air. This equilibration process will not be materially hastened by air flow velocities used in the SASS 3100. That is, CBRN International’s electret filters should not measureably speed up the dehydration of humidity-sensitive aerosols.

The filter element can provide a liquid sample suitable for a wet bioassay after being processed in the SASS 3010 Manual Extractor, or the capture disc portion may be placed directly in a 50 mm petri dish for a culture-based assay.

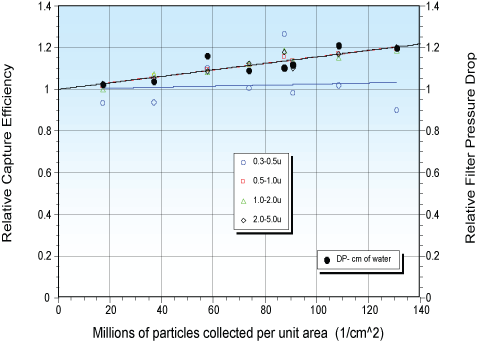

Figure 5 shows capture efficiency for 0.9 µm polystyrene microspheres over an extended 7.5 hr collection period, during which time over 140 million particles/cm2 were deposited. The figure shows that collection efficiency for particulates in the 0.5 to 5.0 µm range actually increased a modest amount, approximately 20%, over that period. The filter pressure drop also increased a modest 20%.

Fan Unit

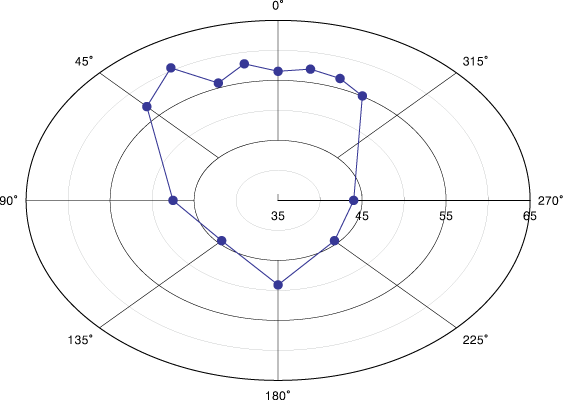

The centrifugal fan is driven by a brushless DC motor with an expected lifetime of 30,000 to 40,000 hours. Fan power consumption is nominally 8 W and noise levels are 45–61 dB (A) at 1 m. Figure 6 shows the effect of rotational position on the maximum sound level. The “zero angle” position corresponds to the centerline of the air discharge port. It can be seen that the peak sound level occurs at a rotational position of 30 degrees relative to the air discharge port position.

Electronics

Electronic subsystems are under the control of an embedded microprocessor, and many operating characteristics such as fan speed and sampling behavior, can be permanently or temporarily changed using Windows© software provided with the system. The unit may be operated manually, by the Windows software, or by other serial port-connected equipment.

An RS-232 serial port is provided. Options include an RS-232 to USB adaptor and a modular RF link that mounts to the RS-232 connector. The standard connector is a commercial DB-9, but a military CCSI style is available.

Long Battery Operating Times

See related Tech NoteThe SASS 3100 can be used with two types of lithium ion-based batteries. The first is a primary type, the BA-5590/U, while the second, the UBI 2590, is a rechargeable battery. Their capacities are respectively 210 and 250 watt-hours at 20C. These capacities translate into continuous run times of approximately 20 and 24 hours, respectively. If the SASS 3100 is on standby, that is, the fan is not running, these batteries can power the units for about 8 and 10 days, respectively.

For customers who will use the sampler frequently, we suggest purchasing the rechargeable battery and its electronic recharger. These two items are about the same price as six primary batteries, so the rechargeable approach may pay for itself in a short time if the SASS 3100 will see heavy usage and the shorter continuous run time with the rechargeable battery is acceptable.

New international air transport rules make shipping batteries with these high energy contents difficult, if not impossible: Batteries must generally be shipped by other methods. If this will make use of the battery-powered SASS 3100 difficult for you, please contact RI for other battery options.

Battery life is monitored in two ways: by ampere-hours of electrical power consumed, and by battery voltage. In the field, a low battery condition is signaled by blinking of the green “Power” LED. When the Sampler is connected to RI’s Windows Operating Software by the serial data link, two indicators of battery life are displayed at the PC- a “Percent Capacity” number based on ampere-hours, and raw battery voltage.

For situations where mains power is available, a universal (IEC 320) wall-plug power supply accepts 82-265 VAC at 47-63 Hz.

Packaging

The electronics and battery are enclosed in a leak-tight extruded aluminum shell. The fan rotor projects from this main enclosure and is coaxially aligned with and protected by a filter mounting plate affixed to the enclosure face. A carrying handle is provided for transport, along with two ¼-20 camera-style female mounting bosses on the carrying handle and the enclosure bottom surface. Overall dimensions are 15 cm W x 17 cm L x 20 cm H, and weight is 1.8 kg.

Decontamination

The system’s pull-through fan minimizes test-to-test contamination. If the unit needs to be decontaminated, it is designed to be washed or sprayed with a 5% bleach solution or subjected to a gas-phase microbicide. The fan rotor housing, which also serves as the filter mount, can be separated for cleaning from the sampler body by simply unscrewing three finger-tight hold-downs. The fan rotor may be sprayed or dunked without removal from the unit: The SASS 3100 is the only air sampler with an exposable rotor that can be decontaminated in situ. Only the motor shaft and fan rotor are exposed when the rotor housing is removed- the motor and electronics are separately sealed. In the event that the motor shaft seal is corroded by repeated decontamination protocols, it is a comparatively simple process to mount a new motor and rotor.

Visit the SASS 3100 product page